Discrete Manufacturing Basics in Dynamics AX 2012

Support for manufacturing in Dynamics AX 2012 rests upon several key concepts:

-

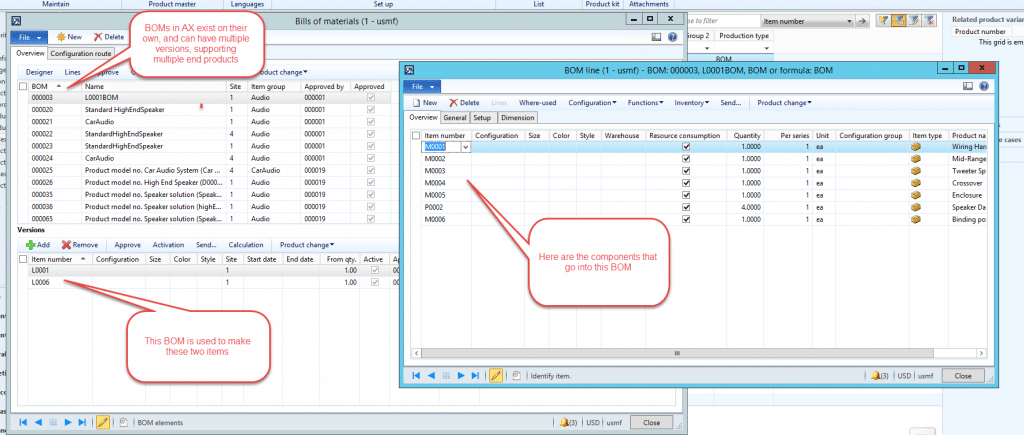

Bill of Materials (BOM):

- The BOM for an item contains every item and service which is valuable enough for financial tracking and/or must be brought to the places where the items is manufactured. A company’s BOMs are among its most valuable data. Well-constructed BOM’s allow for accurate requirements planning and financial controls. They give a company a competitive edge in delivering goods to their customers that are properly (and profitably) made. But in and of themselves, Bills of Material only hold what a product is made of. They do not say how to make it. To be complete, the company needs to list all of the resources available for making products, and describe the processes by which products are made. Note the characteristics of the BOMs as shown on the BOM form:

-

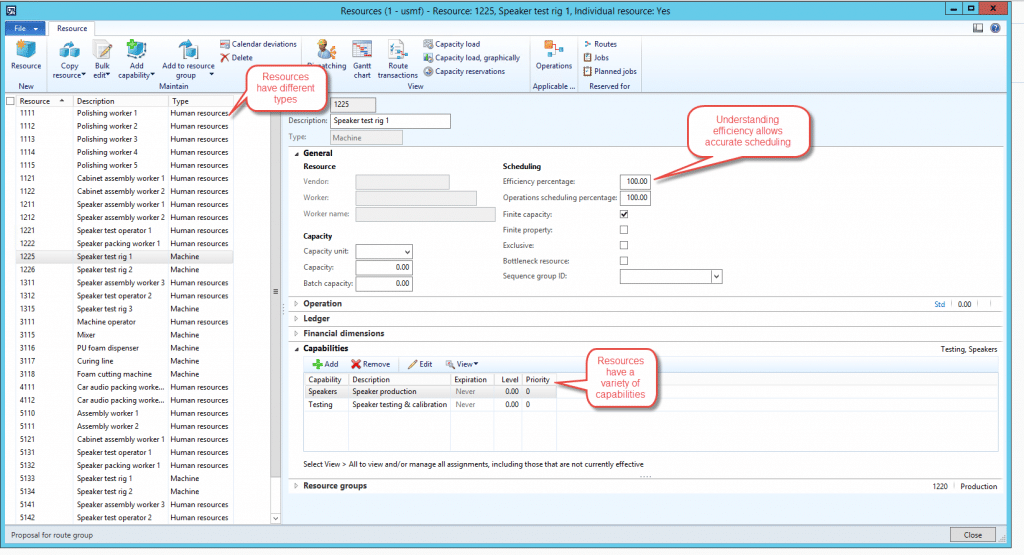

Resources:

- In Dynamics AX, resources are the work centers, tools, machines, vendors, and people needed to produce the goods and/or services made by a legal entity. Basically anything that needs to be tracked and or scheduled that is not on the BOM will wind up declared as a resource.

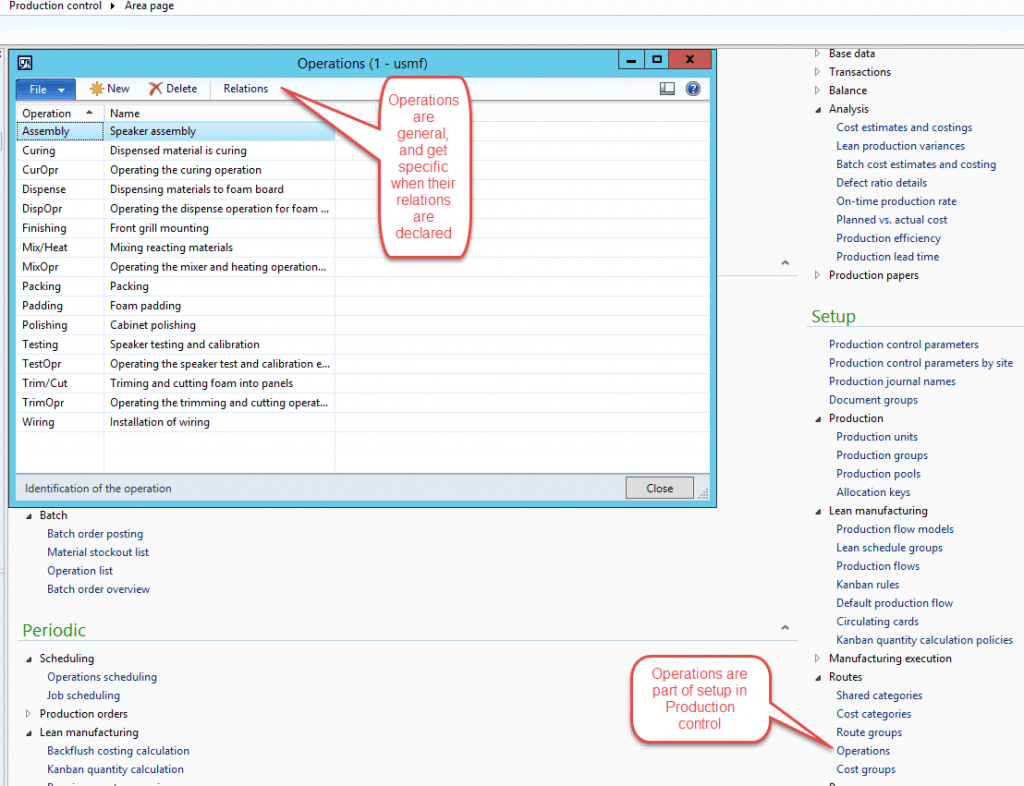

- The BOM and the resources come together in the process steps: in Dynamics AX these are specified in Routes, which declare the order in which things are done, and Operations, which declare what is done. The operations break down the processes into work steps and allot a time value to each. The ability to capture the time that should be spent on each step allows accurate costing and scheduling.

-

Operations generally define activities:

-

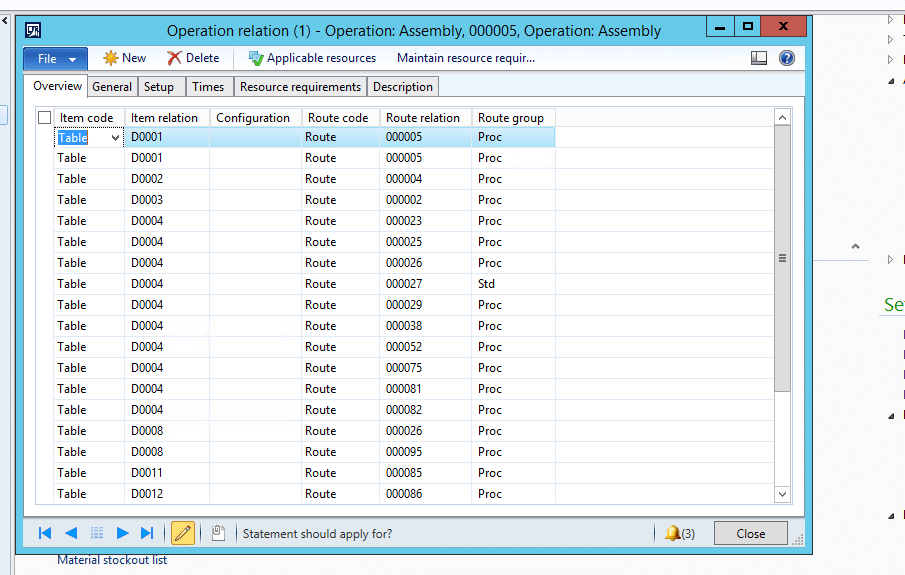

Declaring the relations for an operation:

- Declaring the relations for an operation is where the details of what an operation means for a particular item are defined. The tabs on the operation relation form allow definition of:

- General – detail of the overview

- Setup – consumption calculation and cost categories

- Times – Before and after queue times, setup, run, and transit times

- Resource – links in all the resource types in detail

Once the materials, resources, and processes have been pulled together, we have “What, Who, Where, and How”.

In the next post on Discrete Manufacturing we will add the “When” in discussing the Calendar options available in Dynamics AX 2012.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.